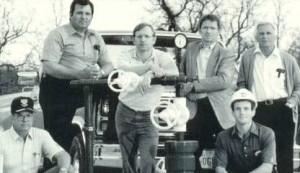

We recently sat down with noted shale geologist Dan Steward to get some first-hand insight in inside the industry from some of the earliest days in shale gas. Steward was part of the pioneering team with Mitchell Energy that revolutionized the shale gas industry, beginning with the Barnett play in Texas.